Precision, Flexibility & Quality in CNC Machining Capabilities

In an industry where large volume orders dominate, Sharp Turn sets itself apart by welcoming orders for as few as 25 pieces up to 20,000 and above. We believe that every project, regardless of size, deserves the highest standard of quality and attention to detail. At Sharp Turn, we bring your designs to life with exceptional precision, efficiency, and speed. Do we really want to promote runs this small?

Advanced Equipment for Superior Results

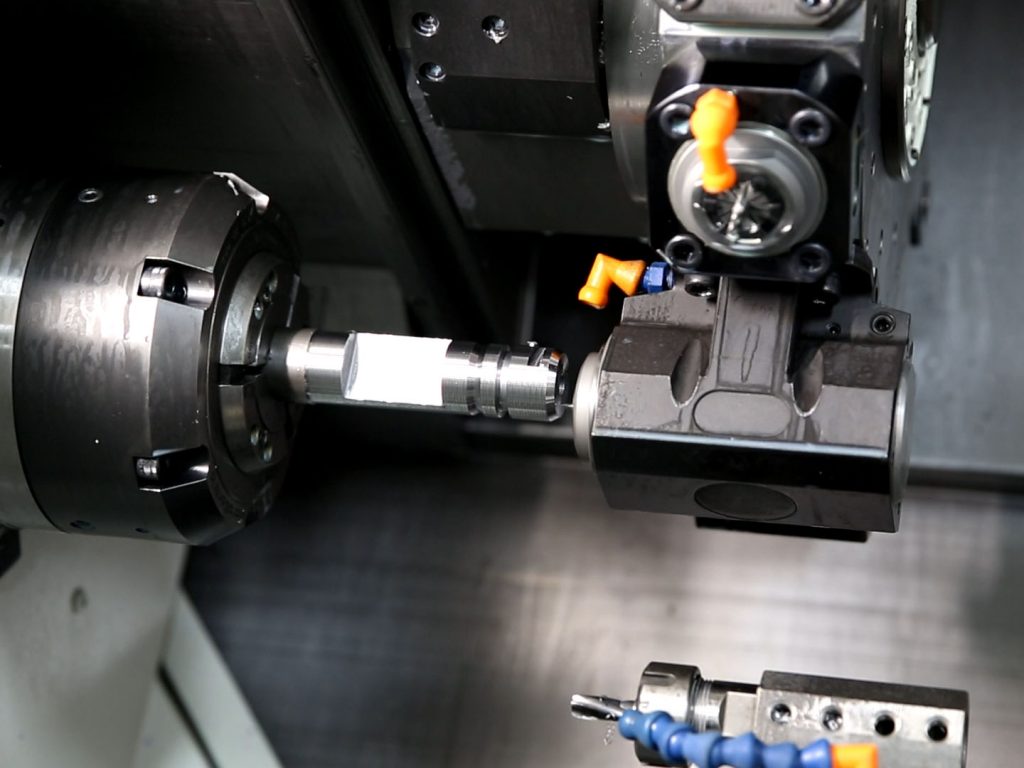

At Sharp Turn, we utilize state-of-the-art equipment to handle a variety of projects with unparalleled precision:

- Six-axis CNC Swiss machining style live tool & sub-spindle screw machines equipped with magazine bar feeders.

- Six-axis CNC turning centers featuring live tools and sub-spindles, also paired with magazine bar feeders.

Versatile Machining Capabilities

Our versatile machining capabilities allow us to work with a wide range of materials and specifications:

- Material Handling: We can machine round, hex, or square stock in any machinable ferrous, non-ferrous, and plastic materials, with diameters ranging from 1/4″ to 2″ and lengths up to 12″.

- Multi-Axis Precision: Our X, Y, and Z axis revolving tools can drill, slot mill, end mill, tap, and contour in a single operation.

- Dual-End Machining: Live sub-spindles enable us to machine both ends of a part, eliminating the need for re-chucking and ensuring higher accuracy.

- One-Operation Production: We achieve highly accurate and repeatable production in one operation, a task traditionally requiring multiple machines.

- Rapid Changeover: Our rapid tool and program changeover capabilities are ideal for prototypes and short runs, ensuring quick and efficient project completion.

International Competitiveness

Sharp Turn is not just about meeting standards but exceeding them. Our internationally competitive processes ensure that you receive the best value for your investment, no matter where you are located.

Experience the difference that true dedication to quality and precision can make. Let us transform your ideas into reality with unmatched expertise and commitment, contact us today!